Do you need a semi-automatic or fully-automatic machine? Should you get a turntable machine, a rotating-arm wrapper or a robotic unit? Knowing which types of machines are suitable for what you are wrapping is paramount.

Automatic or Semi-Automatic?

How many pallets are you dealing with daily? If you're handling 10-100 pallets per day, a semi-automatic machine is the better option. However, if you're dealing with 200 pallets or more per day, an automatic machine will provide more speed and efficiency for that throughput.

Semi-automatic pallet wrappers bring some automation to the primary function of the machine - wrapping the pallet. The operator loads the pallet to the turntable, chooses their settings, attaches the end of the film, then starts the wrapping cycle. The wrapper completes its wrap cycle, coming to a stop at the end, at which point the operator cuts the film and attaches the end to the pallet.

Automatic Pallet Wrappers automate more functions of the semi-auto pallet wrapper in regards to the attaching and cutting of the film. For these machines, the operator simply loads the pallet onto the table, chooses their settings, and starts the process. The wrapper automatically attaches the film to the pallet, goes through the wrapping process, then cuts and attaches the film at the end - all while the operator is free to work on other tasks. These machines are typically required to have safety systems like mesh guarding to prevent people from getting too close to the machine while it's operating. Our Prowrap model features a laser sensor that acts as an invisible barrier, should anyone wander too close to the machine, it will stop operating until they leave the area.

Rotating Table, Rotating Arm, or A Robot?

Rotating tables are the most common pallet wrapper type, but there's a couple of situations where another type of machine might need to be considered.

Rotating Table: These machines have a rotating turntable which the pallet is placed on, it then rotates to wrap the pallet. The ONEWRAP machines are the best example of this - so long as your loads aren't weighing more than 2400kg, a rotating table is usually the most cost-effective and common machine type.

Any pallets weighing over 2400kg will require an alternative method for wrapping.

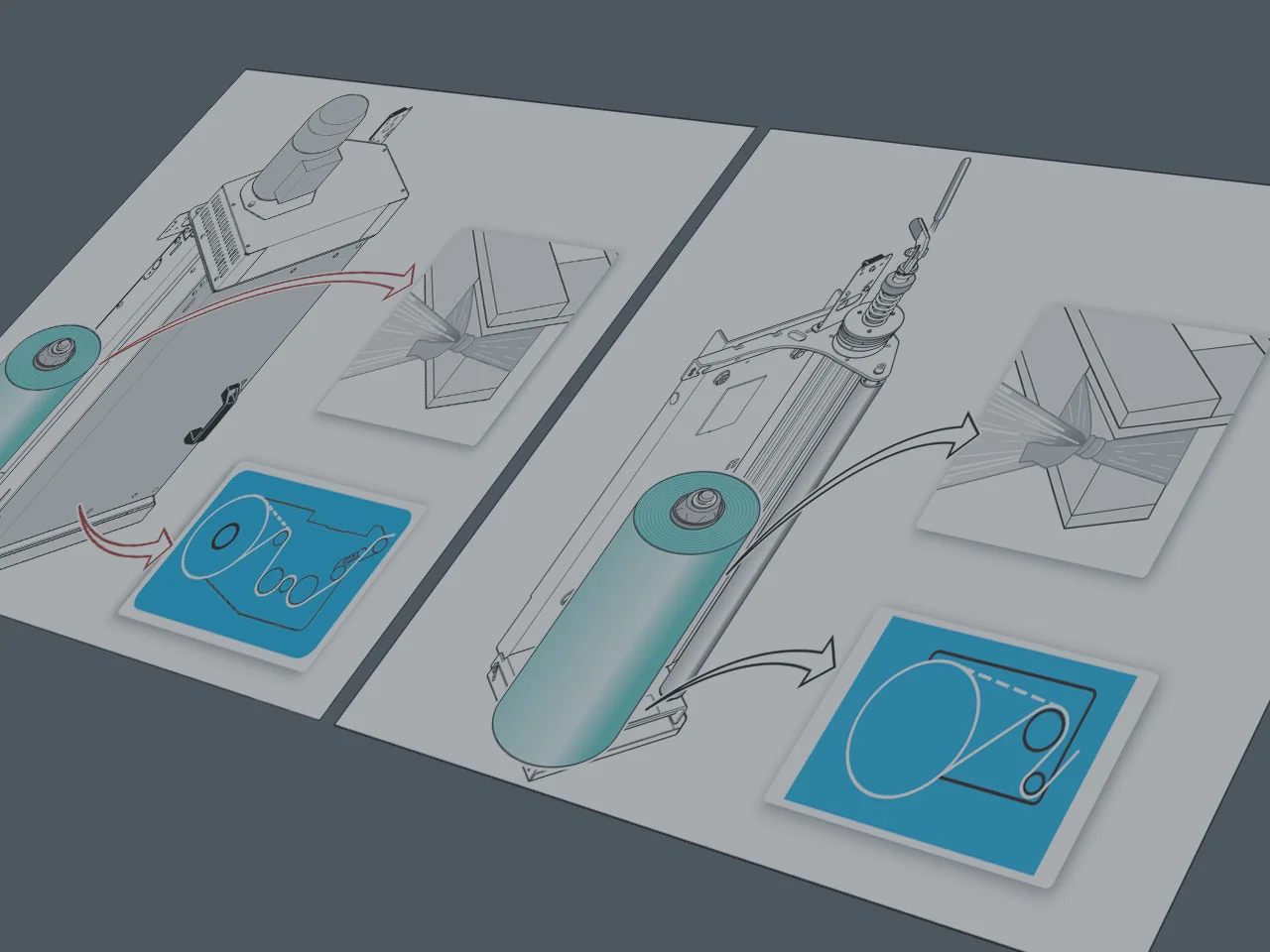

Rotating Arm: These pallet wrappers are ideal for very heavy or unstable products. As this wrapper does not have a turntable, the pallet remains on the ground, allowing the wrapping of loads of any weight. It also works well for unstable pallets. Rather than spinning the load on a turntable, the pallet wrapper instead moves around the stationary pallet.

Robotic: A relatively new style of machine for the NZ market, the BEEWRAP machines are equipped with wheels and powered by high-performance batteries that will allow then to wrap up to 300 pallets per charge. They operate on the same concept as the rotating arm wrappers: leave the load stationary and move the wrapper around the pallet. Robotic pallet wrappers are generally a lower-cost alternative to rotating arm machines, with the added advantage of being able to be moved anywhere in the building. On top of wrapping incredibly heavy pallets, it can also handle extremely lightweight pallets, down to a 25kg total pallet weight - making them particularly well suited to plastics manufacturers and other companies who distribute lightweight, but large pallets.

Next Article: